Welcome to the official website of Laizhou Huayin Test Instrument Co., Ltd!

Huayin Products

420HRSS-150ZT3.2 fully automatic (Jominy test) full-scale Rockwell hardness tester

莱州华银试验仪器有限公司

Classification:

Key words:

Huayin Test Instrument

Summary:

Professional R & D and production of metal, non-metallic materials hardness tester

I.Product Introduction:

The 420HRSS-150ZT3.2 fully automatic(Jominy test)full-scale Rockwell hardness tester is a precision electronic force-controlled fully automatic Rockwell hardness tester that can automatically perform multi-point and batch measurements of Rockwell hardness,automatically generate inspection reports,and draw displacement-hardness curves or end-hardening curves for samples.The testing process is fully automated.Put the sample on the device and press the"Start"button to obtain multiple hardness values for each sample.End-hardening test is a standard method for determining the hardening ability of certain metals and alloys.The device meets the standards GB/T225 and ISO 642"Steel--Hardenability test by end quenching(Jominy test)",and ASTM A255"Test method for the determination of hardenability of steel";the accuracy of the hardness tester meets GB/T 230.2 ISO 6508-2 and ASTM E18.

II.Main features:

● The hardness tester is a fully automatic digital display full-scale Rockwell hardness tester with high testing accuracy.It can be used separately from the automatic end-quenching system and can meet different Rockwell hardness testing requirements.It has a novel appearance,complete functions,easy operation,clear and intuitive display,and stable performance.

● 8-inch LCD touch screen interface,simple and convenient operation,can display the current test scale,test force,test indenter,holding time,hardness conversion value,indenter type,etc.;

● One-click start,automatic Z-axis lifting,automatic workpiece approach to the indenter,automatic loading of test force,sensor force closed-loop control,automatic completion of the entire testing process,and display of the tested hardness value on the screen;

● The XY automatic coordinate test bench automatically moves along the X-axis and Y-axis directions according to the settings;

● Automatic application of initial test force and main test force,automatic application,maintenance,and removal of test force;

● Automatic compensation of test force,high force accuracy;automatic correction of convex hardness value;

● With software calibration function;the test process dynamically displays the displacement-force curve for easy observation and analysis;

● The upper and lower limits of hardness testing can be set,and the buzzer will automatically indicate when the hardness exceeds the limit;

● A total of 30 scales,including 15 Rockwell hardness scales and 15 surface Rockwell scales;

● Chinese and English language interface conversion;various hardness value conversion;

● Equipped with USB and RS232 data interfaces,it is convenient for users to process data;

● With database storage data function,test data is synchronized and exported;

● Equipped with a micro printer,it can directly print the hardness test results;

● The accuracy of the hardness tester complies with GB/T230.2 ISO6508-2 and American ASTM E18;

● In the end quenching test,the end quenching device can automatically measure the hardenability curve of up to 6 end quenching samples at a time;

● The fully automatic end-quenching test can be conducted with self-defined coordinate points for batch testing,greatly improving efficiency;

● Various fixtures can be customized to perform batch testing on different samples;users can customize dedicated inspection reports;all continuous test data can be exported to the report multiple times or in one time.

III.Technical parameters of the host machine:

● Rockwell measuring range:20-95HRA,10-100HRBW,10-70HRC

● Surface Rockwell measurement range:70-94HR15N,42-86HR30N,20-77HR45N,67-93HR15TW,29-82HR30TW,10-72HR45TW

● Rockwell test force:588.4,980.7,1471(N)

60、100,150(kgf)

● Surface Rockwell test force:147.1,294.2,441.3(N)

15、30,45(kgf)

● Measuring scales:HRA,HRBW,HRC,HRD,HREW,HRFW,HRGW,HRHW,HRKW,HRL,HRM,HRP,HRR,HRS,HRV,HR15N,HR30N,HR45N,HR15TW,HR30TW,HR45TW,HR15X,HR30X,HR45X,HR15Y,HR30Y,HR45Y,HR15W,HR30W,HR45W

● Conversion scales:HRA,HRBW,HRC,HRD,HR15TW,HR30TW,HR45TW,HR15N,HR30N,HR45N,HV,HBW

● Resolution:0.1HR

● Hold time:0-99s

● Maximum allowable height of sample:130mm

● Removal of automatic coordinate test bench:300mm

● Distance from the center of the indenter to the wall:160mm

● Power supply:AC220V,50Hz

● Overall dimension:533x230x875(mm)

● Weight:about 155kg

IV.Parameters of XY automatic coordinate test bench:

● XY automatic stage adopts a new dust-proof structure,driven by high-precision ball screw and guided by precision linear guide rail,effectively ensuring high precision,high load,long life,good dust prevention and other characteristics;

● Automatically move the sample to the next measurement position,with fast movement and high accuracy of movement distance.Automatically control the sample movement distance,with a maximum process of 100mm and a minimum step size(resolution)of 0.01mm.The number of measurement points and measurement positions can be set according to corresponding standard requirements or manually entered parameters.

● Specimen clamping device:easy to load and unload,can hold 1-6 end-quenching samples at a time;

● The stage platform size is 130mmx120 mm;the operating accuracy is 0.003 mm;the X Y axis stroke is 100 mm,and the maximum center load is 30 Kgf;

● X-Y stepper motor drive device;Rockwell test software automatically controls the test process,analyzes and displays the test results;

● Automatically generate inspection reports and plot the hardenability curve of the sample;can prepare and store test methods,and directly call out the test methods and test data for the next test,without the need to re-prepare and calibrate the test methods.

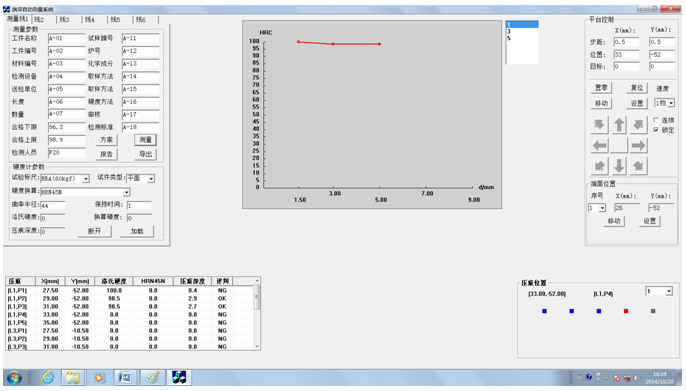

V.Software interface:

VI.Main attachments:

● XY automatic coordinate test bench:1pc.

● Automatic coordinate test bench controller:1pc.

● Special control software:1 set

● Special fixture for test:1 set

● Small flat test bench:1pc.

● V-shaped test bench:1pc.

● Diamond conical indenter:1pc.

● Φ1.588mm tungsten carbide alloy ball indenter:1pc.

● Standard Rockwell hardness block:5 pcs.

● Standard surface Rockwell hardness block:4 pcs.

● Mini printer:1pc.

● Brand computer:1pc.

Message consultation

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Related Products

Rockell Hardness Tester Series

HUAYIN

Rockell Hardness Tester Series

HUAYIN

Rockell Hardness Tester Series

HUAYIN