Welcome to the official website of Laizhou Huayin Test Instrument Co., Ltd!

Huayin Products

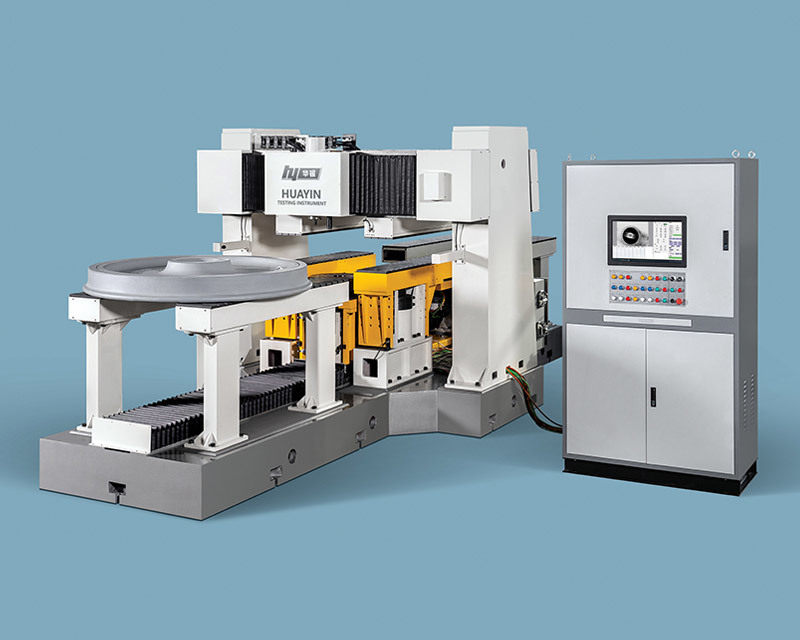

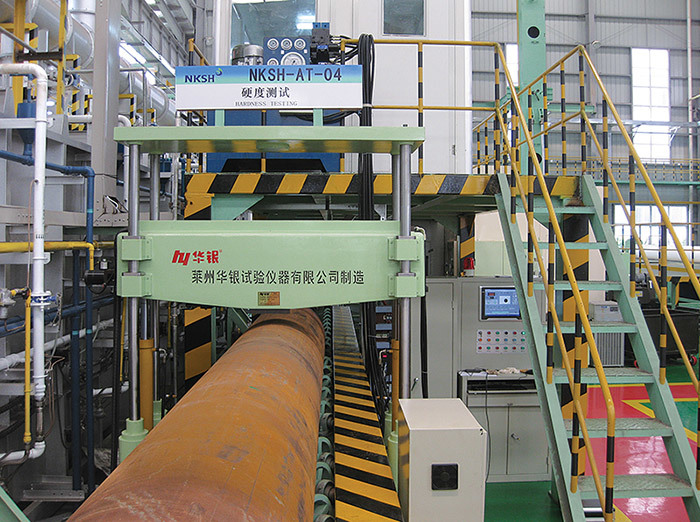

Intelligent online automatic Brinell hardness tester

莱州华银试验仪器有限公司

Classification:

Key words:

Huayin Test Instrument

Summary:

Professional R & D and production of metal, non-metallic materials hardness tester

Product Introduction:

The unattended intelligent online automatic Brinell hardness tester adopts an industrial computer control system to achieve automatic clamping of workpieces,milling(grinding and polishing)of test surfaces,indentation and automatic measurement of indentation.It has intelligent workpiece access and milling(grinding and polishing)depth control functions;a closed-loop control system for test force and an automatic CCD indentation capture measurement system,which enables unattended operation;automatic transfer of test data into an Access database and printing records.

Application range:

● This hardness tester changes the traditional sampling and testing method,and is an online direct test during the entire production process,achieving 100%hardness testing of workpieces.

● It is mainly used for round disk-type workpieces(such as high-speed railway wheels),shaft-type workpieces(such as gas cylinders,steel pipes,drill pipe collars,etc.),and box-type parts(such as engine cylinder blocks,cylinder heads,etc.).

Main features:

● The project was listed as a funded project of the"Technology Innovation Fund for technology-based small and medium-sized enterprises"by the Ministry of Science and Technology in 2011,and passed the acceptance inspection in 2014

● Using independently developed invention patent technology,"bistable direct-drive hardness tester spindle with unloading unit"(patent No.:ZL201410617454.3),integrates Brinell hardness test head technology to accurately apply and remove test forces,achieves closed-loop control of the hardness tester's test forces,and improves the accuracy of the test forces;

● Using the"telescopic CCD hardness indentation optical measurement device"(patent No.ZL2022 2 1907241.0),it eliminates the impact of external stray light on imaging quality and automatically completes precise indentation measurement without manual measurement;

● The equipment itself has an automatic clamping function,and its clamping force constitutes the internal force of the equipment,enhancing the rigidity of the equipment and providing a guarantee for milling(grinding and polishing),eliminating the impact of vibration on hardness testing on the production site;

● Automatic milling(grinding and polishing)of the tested workpiece area to form a hardness testing plane,improving testing accuracy;

● The clamping,milling(grinding and polishing),indentation,indentation measurement of the measured workpiece are automatically completed in one time clamping,and the relevant requirements of the hardness test are automatically completed with high efficiency;

● The robust gantry structure frame has good rigidity and meets the hardness testing requirements of the workpiece production site;

● Pre-set upper and lower limits for hardness values,automatically determine whether it is qualified,and have sound and light alarm prompts;

● Preset test conditions(including workpiece material,model diameter,test date,operator,etc.)

● The test data is automatically saved to the database for traceability at any time;

● The accuracy meets GB/T231.2-2022 ISO6506-2.

Technical parameters:(can be determined according to the actual situation of the user)

● Test force:3000kgf,1000kgf,750kgf,500kgf

● Measuring range:8~650HBW

● Tungsten carbide ball indenter:diameter 5mm,10mm

Main attachments:

Provide according to the actual situation,agreement requirements,and user needs

Next

Message consultation

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Related Products