Welcome to the official website of Laizhou Huayin Test Instrument Co., Ltd!

Huayin Products

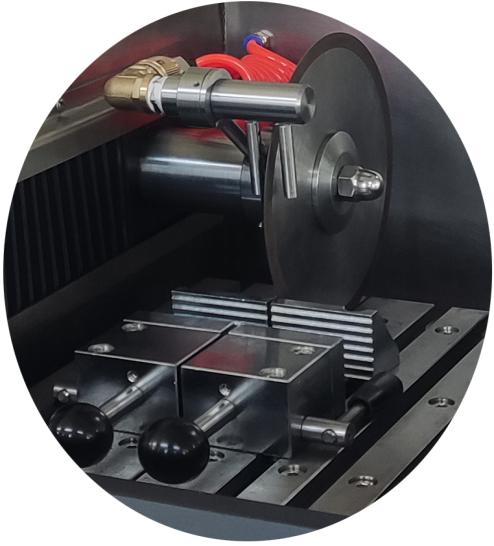

GT-5000B High-Speed Precision Cutting Machine

莱州华银试验仪器有限公司

Classification:

Key words:

Huayin Test Instrument

Summary:

Professional R & D and production of metal, non-metallic materials hardness tester

The GT-5000B high-speed precision cutting machine is suitable for precise, deformation-free cutting of materials such as metals, electronic components, ceramic materials, crystals, hard alloys, rock samples, mineral samples, concrete, organic materials, and biological materials (teeth, bones). This equipment has high positioning accuracy; a wide speed adjustment range; strong cutting capability; a robust circulation cooling system; preset feed speeds; a touch screen control display for easy operation; and automatic cutting to reduce operator fatigue, ensuring consistency in sample preparation. It features a touch screen for human-computer interaction and uses a high-precision stepper motor for control, along with a spacious, bright cutting chamber equipped with a safety switch. It is one of the ideal devices for preparing high-quality samples in industrial enterprises and research institutions.

Note: This system is a servo-driven system, requiring stable input voltage. If the input voltage fluctuates too much, please equip a voltage stabilizer!

Product Features:

- 7-inch color high-definition touch screen, intuitive operation, simple and easy to use;

- High-power, high-torque servo motor, integrated control, stepless speed regulation, strong cutting capability;

Main Technical Specifications

|

Name |

GT-5000B High-Speed Precision Cutting Machine |

|

Cutting Blade |

Standard configuration φ200mm×φ32mm×1mm |

|

Spindle Speed |

500-5000r/min |

|

Feed Speed |

0.01-3mm/s |

|

Manual Feed Speed |

0-15mm/s |

|

Retreat Speed |

0-15mm/s |

|

Impact Cutting Distance |

0.1-2mm |

|

Cutting Stroke (Y Axis) |

200mm |

|

Maximum Cutting Diameter |

φ60mm |

|

Maximum Length of Workbench Clamping |

150mm |

|

Maximum Width of Workbench Clamping |

200mm |

|

Servo Motor |

Power: 1.5KW |

|

Usage Method Data |

Can store 10 types |

|

Power Supply: |

AC220V 50HZ |

|

Dimensions |

750mm×860mm×430mm (±10mm) |

|

Weight |

110KG |

Spindle Speed: Users can set any speed between 500—5000r to adapt to material cutting, effective during stepless speed regulation operation.

Feed Speed: Range 0.01-3mm/s, select a cutting speed suitable for the material to meet cutting requirements, ineffective during operation.

Manual Feed Speed: Range 0-15mm/s, refers to the manual forward and backward speed; when unfamiliar with the equipment, it should be set lower to avoid the cutting blade colliding with the workpiece.

Retreat Speed: Range 0-15mm/s, refers to the speed of retreating to the cutting starting point when the cutting operation reaches the set distance; the larger the setting, the faster the retreat.

Cutting Stroke: Range 0-200mm, set an appropriate stroke to stop cutting when the cutting is completed; continuous cutting of the same sample does not require re-positioning.

Cutting Mode Selection: Two modes for user selection: direct cutting and impact cutting, providing a wider range to meet material cutting needs.

Direct Cutting: This is the ordinary and most economical cutting mode, suitable for most material cutting selections.

Impact Cutting: Suitable for certain specific materials and materials with high hardness where appropriate cutting blades cannot be found, and materials that wear easily can clog the cutting blade, or when the abrasive of the cutting blade is insufficient; impact cutting may lead to higher wear of the cutting blade but reduces the risk of overheating the workpiece.

Impact Cutting Distance: Range 0.1-2mm, effective only for impact cutting mode; the smaller the set distance, the faster the impact cutting speed, and the cutting speed of the workpiece is related to the set cutting speed.

User Parameters: During use, parameters we set can be stored in user parameters; when cutting the same material with the same cutting blade, we do not need to set parameters each time for different samples and materials, making sample cutting more convenient and quick. Currently, it can store 10 items; if more storage is needed, users should specify when purchasing. (10 items display best)

Message consultation

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Related Products