Welcome to the official website of Laizhou Huayin Test Instrument Co., Ltd!

Huayin Products

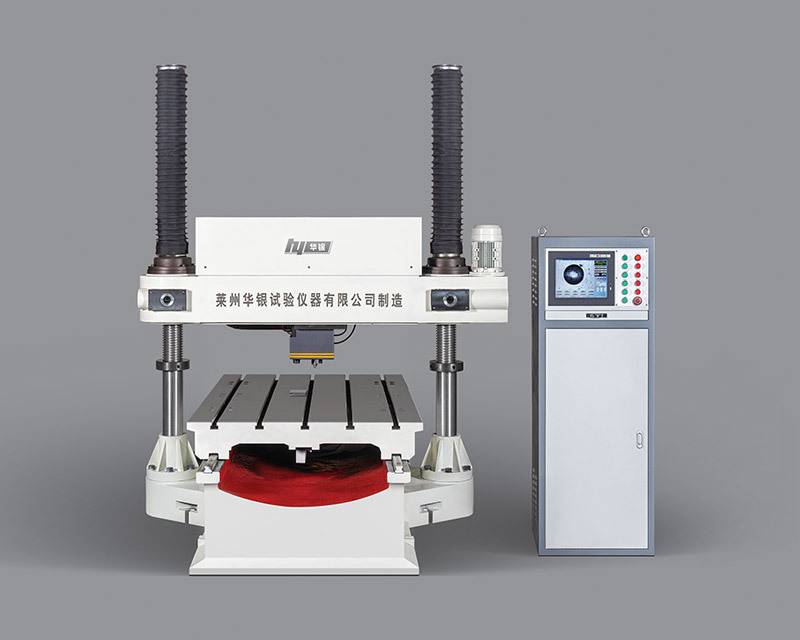

HBMS-3000C digital door type Brinell hardness tester

莱州华银试验仪器有限公司

Classification:

Key words:

Huayin Test Instrument

Summary:

Professional R & D and production of metal, non-metallic materials hardness tester

Main features:

● The application of Pascal's law to design the force-applying mechanism of the test force provides smooth and impact-free operation,effectively meeting the requirements of the Brinell hardness test method;

● The force-applying mechanism of the test force,the pressure sensor,and the Brinell spindle indenter are directly connected to form a Brinell hardness test head technology-a bistable direct-drive hardness tester loading unit,which has obtained one national invention patent and two utility new types patents;

● ARM high-speed processor,fully automatic closed-loop pressure sensor control system,electronic control of loading and unloading test forces,high force accuracy;

● The base,mobile workbench and crossbeam use Huayin's traditional technology,with one-time casting,providing stability,reliability and durability;

● With strong structure and good rigidity,reliable,durable,high testing efficiency;

● Door type frame,large mobile workbench,equipped with linear guide rail,front and rear movement range of 1000mm,maximum allowable height of the test piece is 950mm;the horizontal movement range of the spindle is 620mm;it is particularly suitable for measuring the Brinell hardness of large workpieces;

● Integrated touch screen industrial computer,visual operation interface,setting various test conditions on the computer;

● Automatic loading,dwelling and unloading of test force;automatic test process,simple operation,no human error;

● The HBM-3000B uses a reading microscope to measure the hardness value,and there is no CCD measurement part by the side of the indenter position in the picture;

The HBMS-3000C model uses CCD image measurement system and has the following enhanced features:

● Automatic capture of indentation,automatic measurement of indentation diameter,automatic display of hardness value and voice reporting;

● One-click start,automatic loading-holding-unloading,automatic position shifting of the indenter and camera,automatic indentation measurement and hardness value display,automated testing process,no human error;

● The test report can be output and printed in Word or Excel format;

● Chinese and English language interface conversion;various hardness value conversion;

● It has the function of storing data in the database,synchronizing and exporting test data;

● Equipped with RS232 interface,it is convenient for users to process data;

● The accuracy meets GB/T 231.2,ISO 6506-2,and ASTM E10.

Application range:

● Determination of Brinell hardness of ferrous and non-ferrous materials;

● Determination of Brinell hardness of bearing alloy materials such as lead-based alloys,Babbitt alloys,and tin-bismuth alloys;

● Determination of Brinell hardness of certain non-metallic materials such as rigid plastics and bakelite;

● The Brinell hardness of large parts produced by casting,forging,rolling,and other processes is measured.

Technical parameters:

● Test force:4903.5,7355.3,9807,14710.5,29421(N)

500、750,1000,1500,3000(kgf)

● Test scales:HBW5/750,HBW10/500,HBW10/1000,HBW10/1500,HBW10/3000

● Hardness test range:16-650HBW

● Test force holding time:1-99s

● Maximum height of the sample:950mm

● Distance between two columns:1350mm

● Power supply:AC380V,50/60Hz

● Workbench size:1000x1500(mm)

● overall dimensions:2000x1800x2180(mm)

● Weight of main tester:about 3000kg

Main attachments:

● Flat test workbench:1pc.

● Tungsten carbide ball indenter:1 each ofΦ10 andΦ5mm

● Standard Brinell hardness block:2 pcs

● 20X reading microscope:1 set(HBM-3000B type)

Message consultation

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Related Products